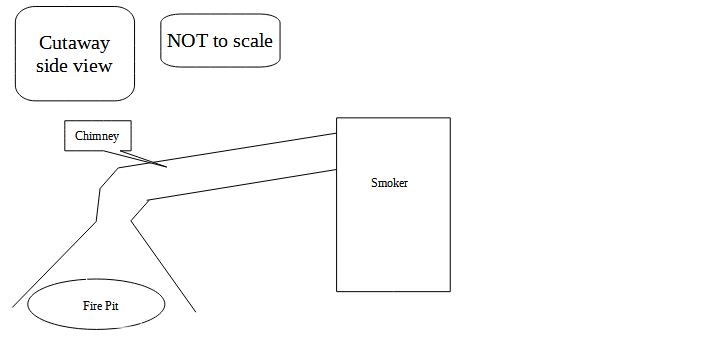

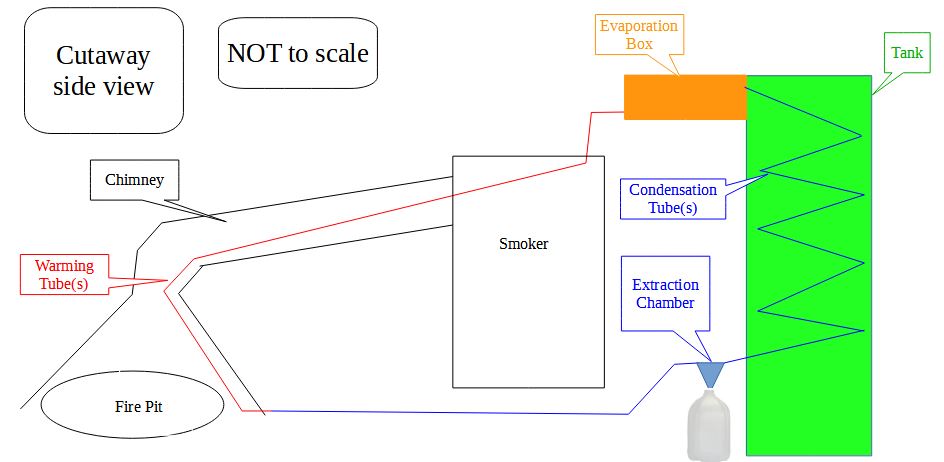

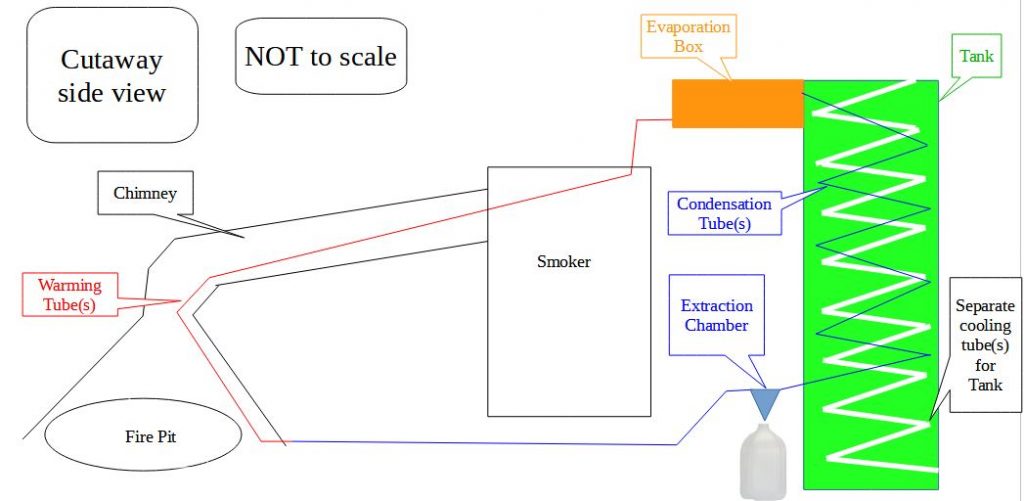

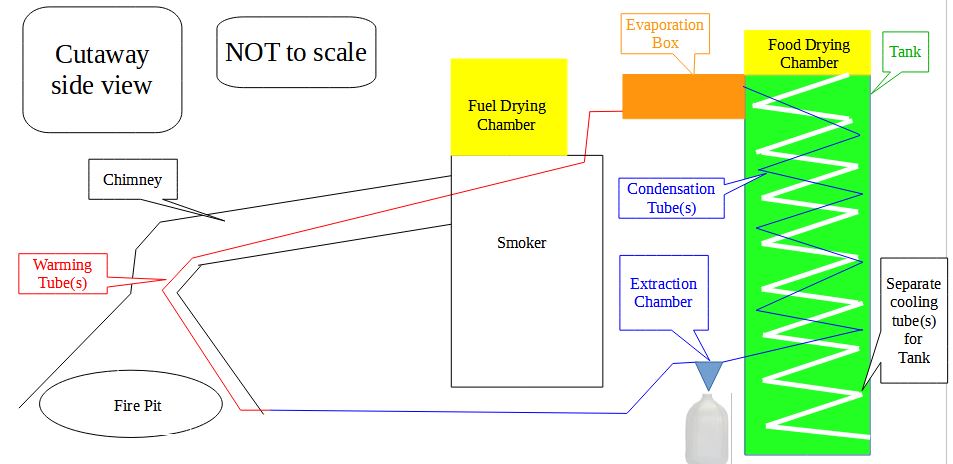

Pre-existing smoker fed by a fire pit

- Hood above the Fire Pit funnels smoke into the Chimney

- openings at ground level for combustion air

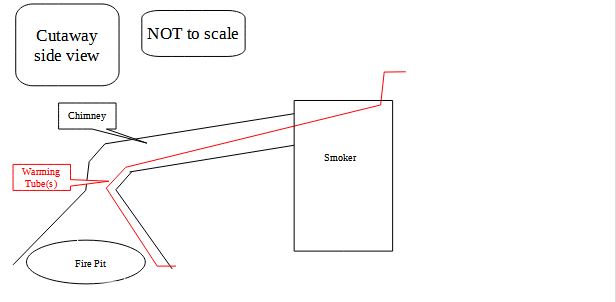

Warming Tube(s) (drawn in red)

- Enters hood at ground level through an opening for combustion air

- extends within Chimney to Smoker

- Exits top of Chimney or Smoker

- Warms and dries Working Air which recirculates endlessly

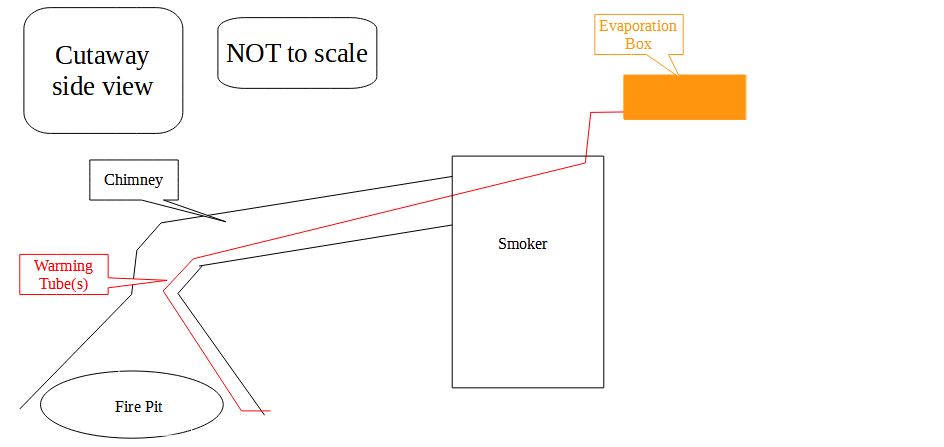

Evaporation Box (drawn in orange)

- Saturates Working Air received from Warming Tube

- 65cm long by 40cm wide by 8cm high.

- Sides and bottom of Box are one piece.

- Top lifts off for easy cleaning.

- Box receives water from Tank

- held to 3cm deep by floating valve (not shown)

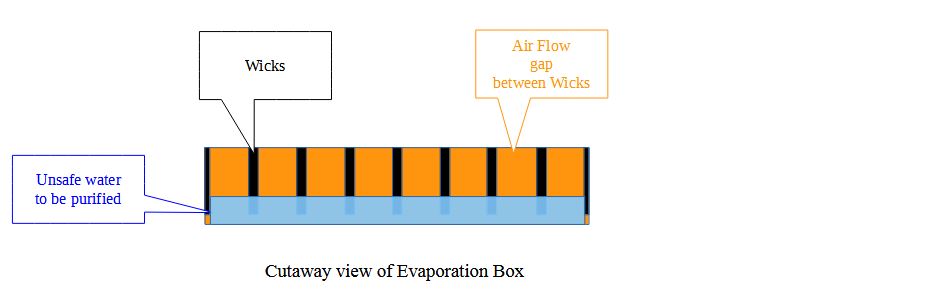

Wicks (drawn in black)

- Stainless steel wool Wicks 65cm long by 7cm tall by 1cm wide hang the length of the Box

- the upper 5cm is the evaporation area; 2cm is in the water and 1cm of water is below the Wicks.

- One of the 1cm wide Wicks is cut into two 0.5cm wide Wicks and hung at the sides.

- This creates seven 1cm wide double sided Wicks plus the two 0.5cm wide single sided Wicks

- making a total of 16 evaporation surfaces

- 16 evaporation surfaces of 65cm by 5cm equals 5,200cm2 of evaporation surfaces.

- Eight air paths between Wicks are 5cm high by 4cm wide

- The bottoms of the air paths are water surface.

Condensing Tube(s) (drawn in blue)

- Inside Tank of unsafe water (drawn in green)

- Receives hot, moist Working Air from Evaporation Box

- Curls down top to bottom within Tank to facilitate cooling

- Runs through Extraction Chamber to deliver distilled water

- Then delivers the cooled, dried Working Air to the Warming Tube to restart the cycle.

Cooling Tube(s) (drawn in white)

- Removes heat absorbed by the unsafe water as the unsafe water cools the hot, moist Working Air in the Condensing Tube

- Ambient air enters Cooling Tube at bottom of tank and leaves at top

- Cooling Tube curls up through Tank to facilitate cooling

Food Drying Chamber

- uses warmed, dried ambient air out of Cooling Tube.

- Being ambient air, it can be made safe for drying food.

Fuel Drying Chamber

- uses the exhaust from the smoker.

- perfect for drying fuel to be used the next day

COMMENTS

- The sizes and arrangements of the components do NOT have to follow the drawings.

- As long as warming air is allowed to rise and cooling air is allowed to fall, everything else is flexible.

- Within the limits of maximum temperature tolerances of your materials:

- Any water tight materials can be used

- Cotton and nylon, etc. can be used as wicking material.

- Any flow of hot air can be fed past the Warming Tube to turn wasted heat into purified water.

- Insulation will increase efficiency

- A Stirling Engine could be used as the Heat Exchange between the fire and the Warming Tube, providing virtually free electricity, but reducing the purified water production.

My research has been done primarily on the internet, so checking my research and checking my math are both worthwhile. Everything I have written here is to the best of my knowledge and belief.

Phil

Contact me at joyfulcatholics@protonmail.com with any questions, comments, complaints.